John

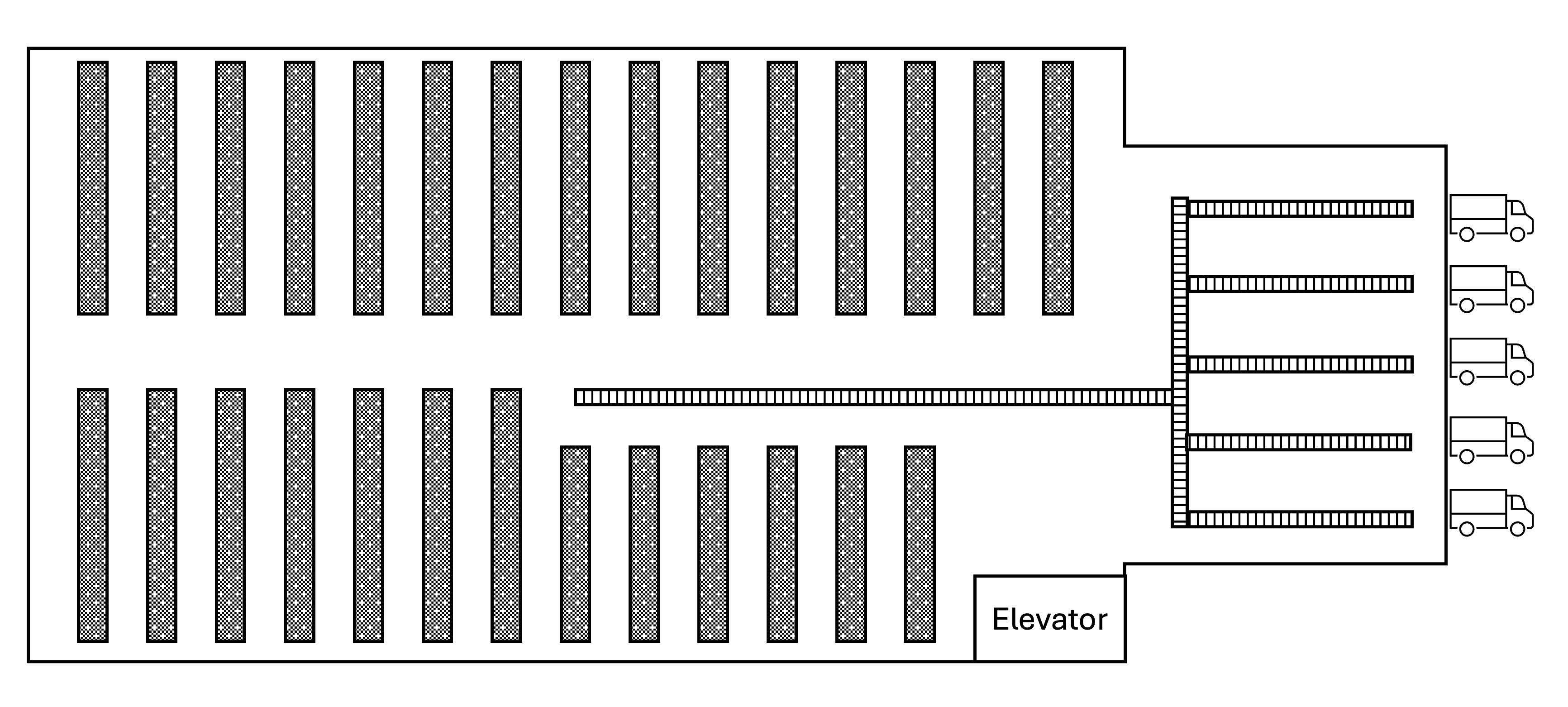

John orders a new computer monitor online and chooses next-day shipping at checkout. Upon placing the order, the e-commerce site's database sends an order to the fulfillment center closest to John, that has the product in stock. This fulfillment center contains a large warehouse floor with 30-foot-tall storage shelves. There is a basement level that is accessible by a large elevator capable of carry heavy loads and is where maintenance department resides. At one end of the warehouse there is a smaller building attached where the shipping department resides. Here, products are packed into boxes and loaded onto trucks. Connecting the shipping department to the warehouse is a conveyer belt that runs down the middle of storage facility center but terminates at the center of the warehouse. Currently, warehouse workers are randomly assigned orders to fulfill and can view them on their tablets. They then utilize order pickers, forklift style machines that lift the workers to the desired shelf so they can manually retrieve the product. Once the items are collected, they are placed in a bin and placed on the conveyer belt. The order bin is then received by the shipping department and placed into a cardboard box by a worker. This box is then placed on another conveyer belt to put on the correct to be sent to the shipping company. At the end of the warehouse workers' shift, they drive the picker onto the elevator to bring it to the maintenance department for charging and any needed repairs.

Figure 1. Illustration of the warehouse layout.

Byte Bay

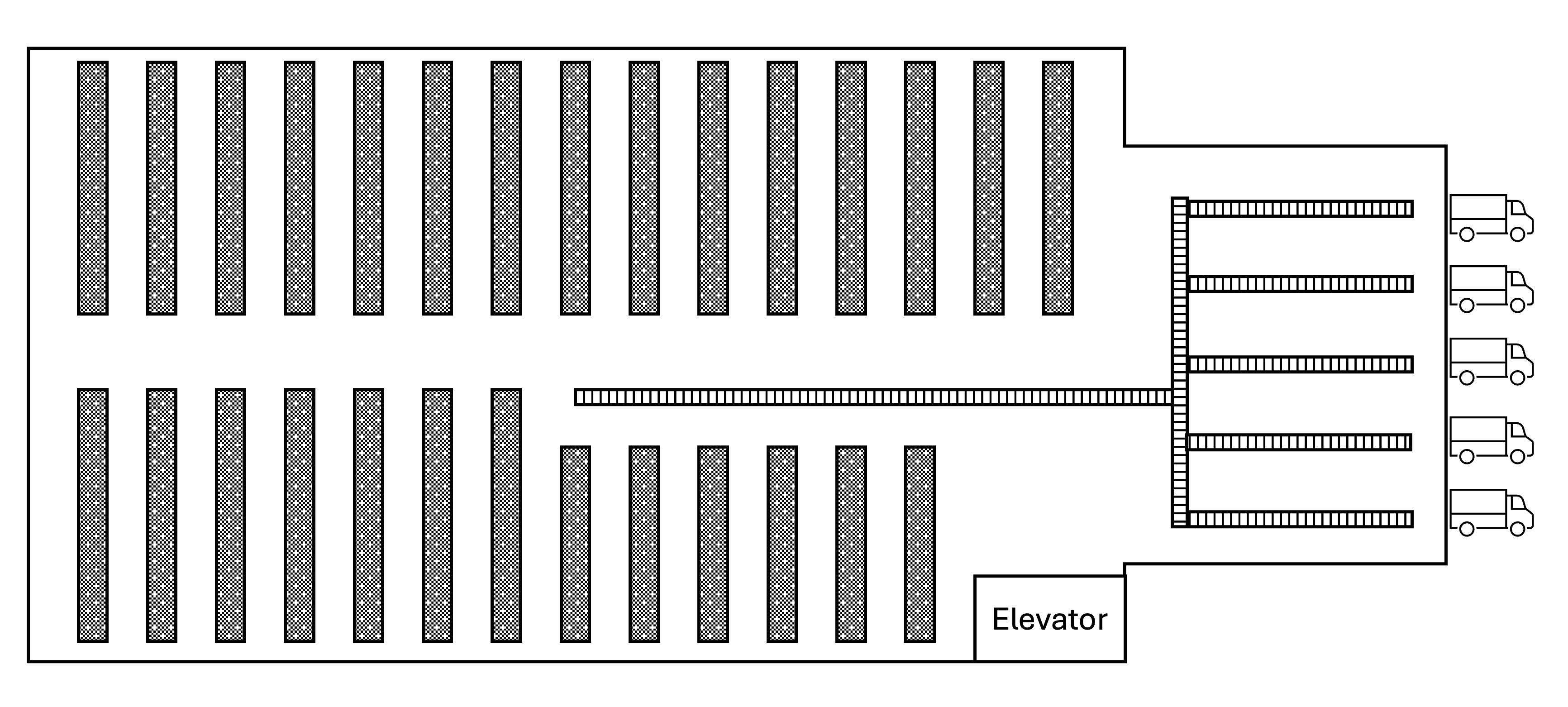

Byte Bay is a large online electronics retailer that sells computers, TVs, phones, gaming systems and more. Leading up to the holiday season, the retailer experiences a drastic increase in sales, which requires an increase in staffing and strains their existing warehouse management systems. The primary fulfillment center is a centrally located, high throughput campus consisting of multiple warehouse buildings. These buildings vary in size, configuration, and automation level, but all contain densely packed racks, which also vary in height. The campus consists of a preexisting network of conveyer belts, forklifts, some automated robots, and warehouse systems. Because new warehouse buildings were constructed at different times, the age and sophistication vary at each warehouse. For example, the newest warehouse has state-of-the art robotic pickers that deliver products directly to the shipping facility via drone or ground robot. Meanwhile, the oldest facility relies on pickers walking and driving order-pickers and club-carts. Naturally, this has resulted in some inefficiencies like misplaced items as a result some warehouses utilize drones to help with inventory management and locating missing items. This retrofit was shown to be a cheaper alternative than refreshing the entire warehouse while keeping jobs in the community. Some buildings are interconnected by tunnels and/or conveyor belts, however, there isn't much consistency. Unfortunately, each system operates independently from one another, and the manufacture varies as well. This results in the facility operating as several co-located fulfillment centers instead of one harmonious fulfilment campus. This can often result in orders being delayed or multiple items placed in one order being shipped separately; raising shipping costs, increasing carbon emissions and leaving consumers to track multiple packages.

Figure 1. Illustration of the warehouse layout.

Figure 1. Illustration of the warehouse layout.